Composite division

The Composites division was born in 1991 from a technical textile development for composite materials molding under vacuum: the VACUOPLEX™, first technical complex of molding under vacuum invented and patented by DIATEX.

Today, the activity and specialty of the Composites division are set around 4 transformation processes:

Composites Vacuum molding,

Composites Vacuum Infusion,

RTM Injection (Resin Transfer Molding),

RTM LIGHT Injection.

In these 4 process technologies, DIATEX’s Composites division brings to end-users:

- Technical support

- A range of technical fabrics

- Vacuum molding consumables

- Vacuum Infusion consumables

- Vacuum machines & systems

- RTM injection machines

- Training space: classes and demos.

The manufacturing process of the Composites division is in the “ECODESIGN” mindset, in response to a strong demand of its clientele.

The goal is to manufacture a range of products more anchored into the environment friendly / ecological trend, within REACH recommendations such as for instance:

- Water-based release agents,

- Biodegradable films,

- Multilayer / multiproduct complexes to reduce waste,

- Single/double sided adhesive fabrics to avoid glue sprays,

- Fabrics manufacturing including waste water reprocessing

DIATEX is a sponsor of the SAMPE France association.

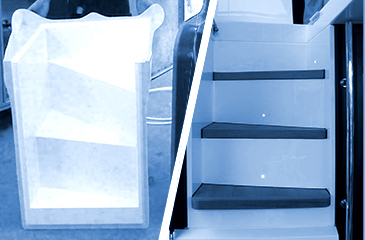

VACUUM MOULDING

DIATEX designed a specific range of bagging materials for prepregs and hand lay-up composite materials with vacuum polymerization. The success of DIATEX is based on the manufacture of innovating products, such as Vacuopeel®, Vacuoplex® and Vacuolease®, whose purpose is to facilitate the application of environmental products by users during drape moulding operations.

DIATEX also offers all standard environmental products as well as the equipment which is used in this manufacture process in compliance with our quality systems.

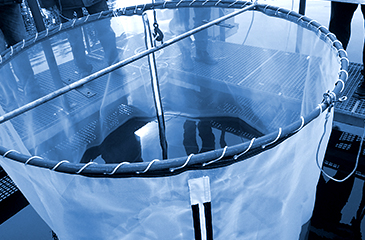

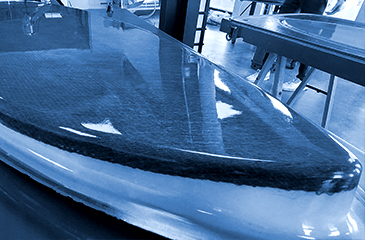

VACUUM INFUSION

DIATEX designed a range of bagging materials for vacuum infusion, a transformation

process often used in boat industry and wind turbine sector.

Positioned at the forefront of technology, DIATEX is constantly developing new solutions to increase the productivity of market operators. DIATEX INFUPLEX® multilayer system combining a fl ow media and a release fi lm is a perfect demonstration of innovation. DIATEX provides a whole range of ecological products and vacuum equipment required in infusion process in compliance with our quality system.

SILICONE REUSABLE MEMBRANES

DIATEX provides a complete range of reusable membranes for infusion, debulking and vacuum moulding in ovens or autoclaves. This range is composed of RTV silicone spray, vulcanized or raw HTV silicone rolls and rubber.

Diatex is able to manufacture silicone tools :

- Silicone tools for infusion (DIASIL 20)

- Silicone zipped bags (DIASILBAG)

- Silicone tools on metal or carbon frame, infl atable bladders

Applications

- Room temperatures : Parablond / Elastibag / Rubberbag

- RTV : Diasil 20

- HTV: Diasil 45 – 50 – 60 – 80

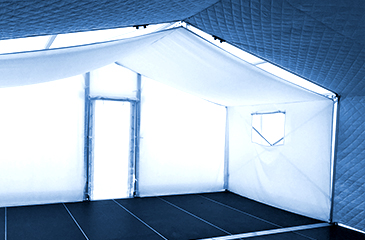

Cleanroom conditions

In order to prepare and stock silicone special DIASIL 50 cuts.