Partners

THE SYNERGY OF SUBSIDIARIES AT THE HEART OF DEVELOPMENT

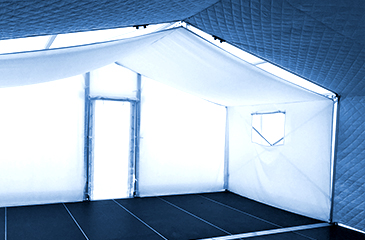

DIATEX quickly engaged in partnerships with its suppliers by forging close bonds with those who have become, over time, subcontractors or even wholly-owned subsidiaries, such as its weaving factory, or textile finishing, with whom the collaboration has made it possible to integrate and control all the links of the textile chain.

Upon customers’ request, DIATEX drafts, with its partners, sets of specifications to define and optimize the technical characteristics of the products. DIATEX also has a garment workshop to meet a very strong demand from its customers by offering custom solutions.

DIATEX can rely on several major partners’ active collaboration, both in terms of its technological activities and its industrial developments. Our strong relationships enable us to offer our customers a better listening experience and a successful product offering, and provide us with a unique vision of future directions and new trends in products and technologies. DIATEX’s 4 subsidiaries are naturally among our privileged partners:

- Tissage des Mûres: weaving unit, 100% acquired in 2015 by DIATEX

- Teinture de St Jean: unit specializing in textile finishing

- Aeroform Composites: a company specializing in hot resources for composites processing

- CIPODEC: a company specializing in tissue cutting, which joined the TDM site in early 2017.

The technological cluster that DIATEX maintains is undoubtedly the source of new developments and DIATEX patents.

We also count among our partners the companies we represent in France. They contribute to our development by providing a complementary range essential and consistent with our production.

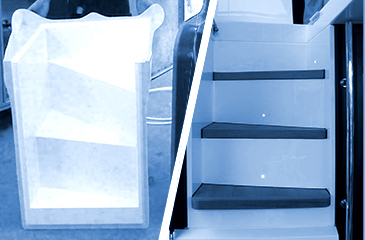

AEROFORM COMPOSITES

Subsidiary of DIATEX, AEROFORM Composites is located in LYON and offers a whole range of high-tech materials for the transformation of composite materials.

AEROFORM Composites is an expert in manufacturing and repairing composite structural parts solutions for international aerospace companies and provides a turnkey solution to all its customers in various fields: electrical, electronics, mechanical design, engineering, dynamic heat transfer, mechanical stress and on-site maintenance.

Since 2001 AEROFORM Composites manufactures and sells heat means for the Composites industry and more specifically for the aerospace sector. The company’s specialty is the Autoclave (from 500mm to 4000mm in diameter) equipped with an advanced control system recognized by the industry.For more than 10 years, the company has also been offering a full range of equipment for composites repair (repair cases, Ecobonder, Hot Gun, Infrared Lamps, Heating Stretchable and Flexible Carpets). This equipment is used on a daily basis by airlines, aircraft manufacturers and maintenance companies, MRO.

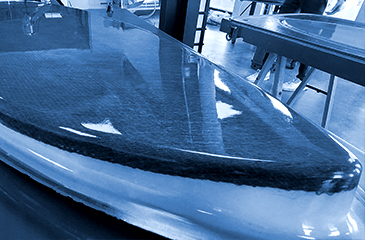

CHEM TREND

CHEM TREND, Global leader in mold release agents, is certified in 2016 according to EN 9100: 2016 by DQS (German Society of Management Systems Certification) and meets the strict quality requirements of aeronautical suppliers.

Over 50 years of experience in manufacturing high-performance products for industries in the molding, foundry and forming sectors has enabled the company to adapt its expertise to different industries’ production processes, even far beyond the products it itself develops and manufactures. This precious help allows production of better quality parts, more efficiently and at a lower overall cost.

CHEM TREND aims to solve any molding issues thanks to environment-friendly innovative solutions, in compliance with the highest ethical standards:

- Making responsible choices which reflect its long-term vision

- Controlling its carbon footprint and its impact on the environment.

The range of release agents includes water-based or solvent-based products, products with or without silicone, in semi-permanent formulations or to be applied during each cycle. DIATEX is a privileged partner of CHEM TREND in Europe, and distributes the ZYVAX product range for aeronautics (AIRBUS and BOEING accreditations).

MIL'S

By developing a specific range for the composites industry in close collaboration with its partner MIL’S, DIATEX offers a full range of pumps and vacuum units at different vacuum levels suitable for vacuum applications.

DIATEX also offers measuring devices to control pressure, temperature and leaks.

MIL’S, French manufacturer since 1926, offers pumps and vacuum plants, air and oxygen generators dedicated to the many professions of Health and Industry. Over the years, MIL’S has been able to develop both on national and international markets, therefore establishing its reputation on several fields of industry. Our multiple vacuum pumps’ technologies, lubricated or dry, whether they are with vanes, nozzles, pistons, screws or liquid rings, enable us to answer all needs in many sectors.

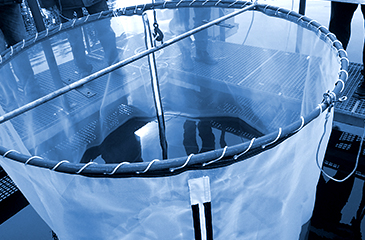

COMPOSITE INTEGRATION

Composite Integration Ltd is as company based in Plymouth UK, which provides services as well as equipment for the RTM and RTM Light casting industry.

Founded in 2002, the company benefits from a wealth of experience in the RTM injection field. Since then, the company aimed to make the best out of its legacy, in order to develop a new generation of RTM machines and equipment.

Founded in 2002, the company benefits from a wealth of experience in the RTM injection field. Since then, the company aimed to make the best out of its legacy, in order to develop a new generation of RTM machines and equipment.

The RTM CIJECT range of machines is a concentrate of technology and innovation, in harmony with an innovative design: Composite Integration Ltd offers the safest and most ergonomic machines on the market.

Over the last few years, the company has extended and modernized its range: machinery, accessories, tooling design…

In close collaboration since 1992, the co-directors of Composite Integration Ltd chose DIATEX to be their brand representative on the French, Moroccan, Tunisian and Swiss markets.