The automatic vacuum pumps are perfectly adapted for composite industry :

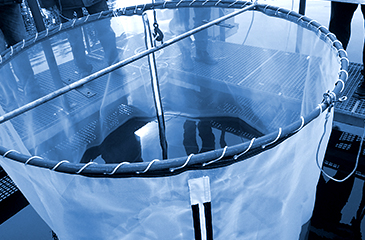

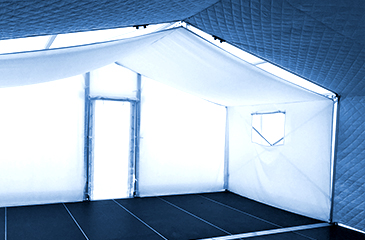

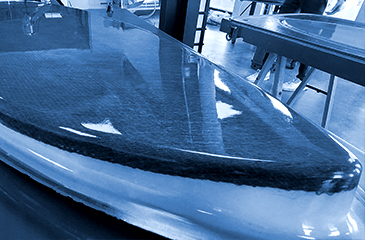

- Vacuum moulding

- Vacuum infusion

- RTM or RTM LIGHT

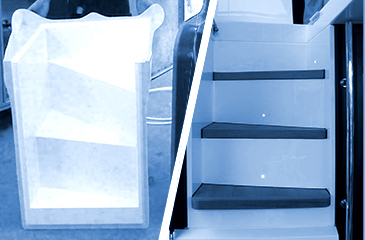

- Lubrificated rotary vanes vacuum pumps

- Standardization of spare parts for an easier maintenance

- Possibility to have a customized protective cover

- Continuous running from atmospheric pressure to end vacuum

- Air cooling

- Standard motor coupling

- P 55 Motor – F class

| Normal capacity m3-h | 50Hz |

Power pump Kw | 50hZ |

End vacuum mbar | HV |

Weight (Kg) | |

| ROTOMIL’S | ||||

| K04 | 4 | 0.12 | < 2 | 5.4 |

| K08 | 8 | 0.25 | 10 | |

| K12 | 12 | 0.45 | 14 | |

| EVISA | ||||

| E65.3* | 64.3 | 1.50 | 1,5.10-1 | 75 |

| E100.3* | 96 | 2.20 | 85 | |

| E17.3 | 19.2 | 0.55 | 5.10-1 | 36 |

| E25.R | 28 | 0.75 | 6.10-1 | 39 |

| E40.R | 47.7 | 1.10 | 52 | |

| E150.R | 132 | 3.00 | 154 | |

| E200.R* | 198 | 4.00 | 140 | |

| E300.R* | 288 | 5.50 | 162 | |

*ATEX version available for explosble atmospheres regarding to INERIS Certificate (standard temperature security).