DIATEX develops an Artificial Intelligence Program

DEVELOPMENT OF AN ARTIFICIAL INTELLIGENCE PROGRAM

In collaboration with ENE, Ecole Centrale de Lyon, La Région Auvergne-Rhône-Alpes and Tissages des Mûres (Diatex Group)

Context :

Lyon-based group Diatex, member of FrenchFab and BPI France, leader in synthetic yarn weaving, OEKO-TEX® STANDARD 100 labelled since 2012, specialises in technical fabrics and the processing of composite materials. Design, Development, Innovation and Manufacturing are the core competencies of the group, whose clients include Boeing, Airbus, Vestas (wind turbines) and Bénéteau (boats).

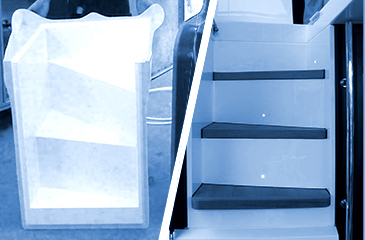

The weaving plant, made up of 2 workshops AIR and WATER, provides a solution adapted to any kind of development thanks to the presence of very wide air jet looms up to 5m40, reaching a capacity of 1000 strokes/minute and new generation water jet looms.

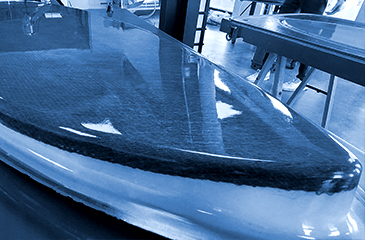

Diatex, positioned on niche markets in the high-tech sector, counts amongst its customers, industrialists from the Aeronautics industry (60% of the activity). Each fabric development is made to specifications with extremely high customer requirements. In response to this need, Diatex has implemented an automated camera inspection system positioned on the machines, to track and analyse the slightest weaving defect to be eliminated (mapping, size, position, type, and coding, visual…). The minimum size of the defects sought is of the order of 500 μm. The current system allows production to be stopped promptly when major defects are identified, significantly limiting their impact.

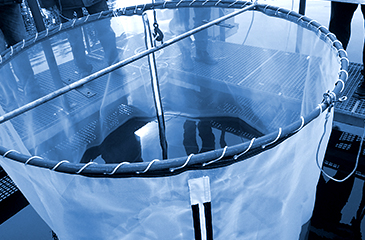

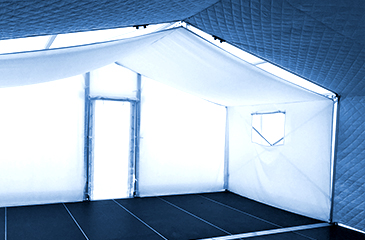

There are 2 main categories of fabrics: those that are visible (airships, parachutes, filtration, etc.) and those that remain invisible because they are part of the manufacturing process of a part (composites, filtration, etc.).

The Diatex group, which has already invested €4.5 million in the modernisation of its industrial facilities and its infrastructure since 2016 including the renewal of 60% of the weaving machines which are less energy-consuming and high-tech, now aims to optimise the potential of its looms with artificial intelligence (AI) and machine learning: how to interpret the data from the automated camera-based technical fabric inspection system.

Project:

In the first half of 2020, Diatex joined the UNR (Usine Numérique Régionale) programme led by ENE and supported by the Auvergne-Rhône-Alpes Region. It is a tailor-made operational programme for the implementation of digital technologies and innovative processes.

Diatex and l’Ecole Centrale de Lyon worked together for a period of 6 months on the “Digital Technology Demonstrator” component, more specifically on the theme of artificial intelligence.

The ENE, whose mission is to improve the competitiveness and favour the innovation of SMEs and VSEs in Auvergne-Rhône-Alpes by developing the use of digital technology, has regularly exchanged with the Auvergne-Rhône-Alpes Region on feedback from Diatex, which is one of the companies benefiting from the experimentation scheme, in the context of the Industry of the Future and innovative technologies.

This project was conducted by a group of 5 students from the Lyon Centrale Digital Lab programme, which is aimed at training professionals in the digital transformation of companies, accompanied by specialists in Design Thinking and agile project management (Scrum method).

In specific terms, the Ecole Centrale students worked on the development of an artificial intelligence capable of automatically qualifying and classifying the defects that appear on the product during the manufacturing process. This is based on a camera control system attached to a database.

The requirement: Creation of a machine for supervision and intelligent data analysis

- Understand and determine the causes according to their nature (source : machine, material, atmospheric conditions, treatments etc.)

- Locating the repeatability and observing the vicinity of defects

- Automate and render data analysis more reliable

- Carrying out a statistical analysis, and creation of indicators

- Perform predictive analysis

- Initiate corrective measures and carry out a preventive plan.

- Make the results of the analysis sufficiently readable to facilitate decision making.

Project objectives

- Perform a comparative analysis to correlate defects between the beginning (weaving) and the end of the manufacturing process, taking into account the phenomenon of shrinkage (differentiated mapping project)

- Creation of a development capable of automating the selection of fabrics deemed “good” or “bad” regarding the CDC imposed by the client.

- Development of a form of artificial intelligence capable of analysing and determining the causes of defects.

- Identify defects that have appeared and disappeared during production,

- Integrating innovation into the current control system

- Suggest ways of improving the current system.

_________________________________________________________________________________________________________________________

The company has been EN9100 certified since 2006. Today, DIATEX has organised its quality approach around certifications and labelling : ISO 9001, EN 9100, and OEKO-TEX® STANDARD 100.

It was also certified by EcoVadis, the global standard for Corporate Social Responsibility (CSR) assessments in 2020.https://www.ec-lyon.fr/formation/diplomes-etablissement/centrale-digital-lab

Programme : « Démonstrateur/Proof of concept » : https://www.ene.fr/agir/unr-demonstrateur-poc/ Fiche programme UNR