Catalog

100% two-part epoxy anti-corrosion primer, pigmented with strontium chromate.

Replaces the previous zinc chromate. Approved by Airbus, British Aerospace and AECMA.

Use :

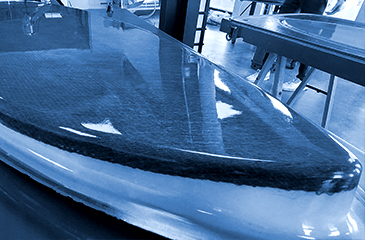

Interior and exterior protection for aircraft producing chemical resistance and a high level of corrosion resistance on substrates prepared with Surface Cleaner.

Application :

Spray gun – for metal aircraft. The viscosity of the mixture is close to that of UHT skimmed milk.

Roller with special foam rolls – for tubular cells.

Brush.

Performance :

High resistance to impacts, synthetic lubricants, phosphate ester hydraulic fluids such as HYJET type IV, salt spray, damp atmospheres, kerosene and filiform corrosion.

Covering power :

10 to 12 sq. m per litre and per coat with a thickness of 20 to 25 μ and 40% loss.

Dry film thickness :

20 to 25 µ.

Time between coats :

Minimum 2 h – maximum 72 h.

Oven drying :

Pre-drying: 30 minutes at ambient temperature.

Stoving: 20 minutes at 60°C before the following coat or 1 h at 80°C or 15 min to 120°C if the primary is not covered.***

Mixture report :

E4120 base : 1 volume.

E0611 hardener : 1 volume.

E0515 solvent : if necessary.