Catalog

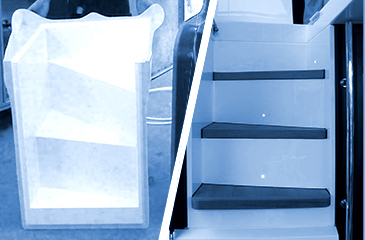

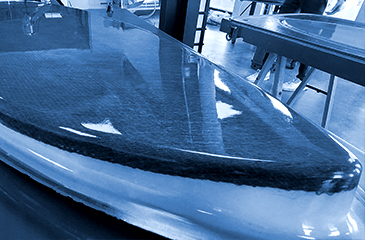

Patented two-layer complex designed for vacuum moulding technology

VACUOLEASE® is available in different configurations : a non perforated or perforated release film, a non woven bleeder (different weight) are linked in only one product.

| Width | Lenght | Thickness |

| 1.50 m | 50 m | +/- 6 mm |

Benefits :

- Drains and protects silicone tools.

- Remove VACUOLEASE® in one part. Prepare VACUOLEASE® with hot knife or scissors.

| PP10P3 / PES150 188 g/m² White / Red |

PP40P3 / PES340 +/- 380 g/m² White / Red |

ETFE P3 / PES150 +/- 185 g/m² White / Blue |

| 1. Perforated film |

||

| PP40 P3 |

PP40 P3 |

ETFE P3 |

| 2. Breather / Bleeder |

||

| PES150 150 g/m² White |

PES340 340 g/m² White |

PES150 150 g/m² White |

| Max. temperature |

||

| 160 °C | 160°C |

205 °C |

Other configurations upon request.

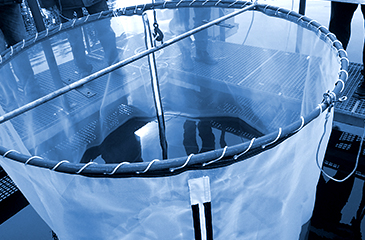

- PROCESS

- Autoclave