Catalog

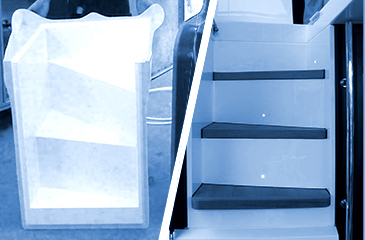

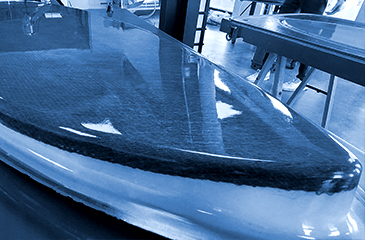

Patented three-layer complex designed for vacuum moulding of composite materials with techniques such as prepreg, wet lay-up, and thermoplastic.

This “smart complex” gives many benefits to the producers : save time, improve the composites quality, one product to buy instead of 3, one product to apply instead of 3. The only difference is on the fact that you can remove the VACUOPEEL® in 2 times after the curing process.

VACUOPEEL® is an evolution of the VACUOPLEX® developed in 1991.

Several versions available. Choose the right one for your application.

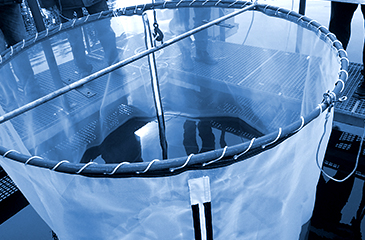

| CARBON APPLICATIONS |

STANDARD / ECO APPLICATIONS |

THIN SURFACES APPLICATIONS |

PHENOLIC RESIN APPLICATIONS |

| PA90 / PES340 470 g/m² Thickness 6 mm |

PA80 / PES200 350 g/m² Thickness 5 mm |

PA64 / PES200 334 g/m² Thickness 5 mm |

PES85 / PES340 470 g/m² Thickness 6 mm |

| 1. PEEL PLY |

|||

| PA90 83 g/m² Pink polyamide + stripes |

PA80 80 g/m² White polyamide + stripes |

PA64 64 g/m² White polyamide + stripes |

PES85 85 g/m² White polyester |

| 2. PERFORATED FILM |

|||

| YES | YES | YES | YES |

| 3. BREATHER / BLEEDER |

|||

| PES340 340 g/m² White |

PES200 200 g/m² White |

PES200 200 g/m² White |

PES340 340 g/m² White |

| Width | Length |

| 1.50 m | 50 m |

- PROCESS

- Oven

- Autoclave

Documentation

Range of bagging materials for prepregs and hand lay-up composite with vacuum polymerization (271 ko)