Catalog

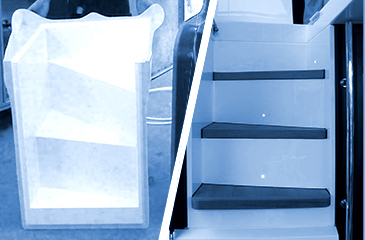

This 3 products combination has been created for the vacuum moulding technology. This patented complex facilitates the implementation of the bagging materials.

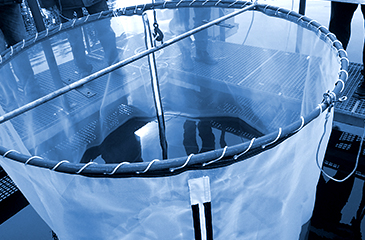

Use VACUOPLEX® on small or big parts in direct contact with the resin (peel ply side incontact with the resin).

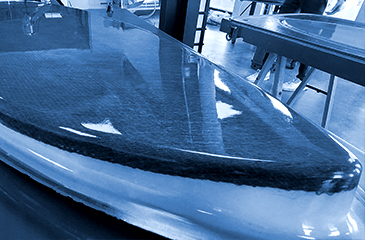

During the curing process, VACUOPLEX® will degas and remove the excess of resin more efficiently compare to the traditional method.

- Productivity gains for the production of advanced

- Remove VACUOPLEX® in one part. Prepare VACUOPLEX® with hot knife or scissors.

| FOR VACUUM MANUFACTURING |

FOR PREPREGS |

| VACUOPLEX 470 g/m² |

VACUOPLEX MP 284 g/m² |

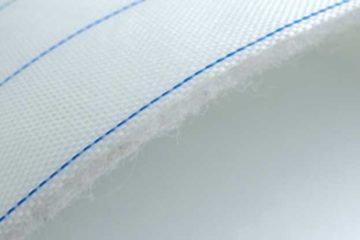

| 1. PEEL PLY |

|

| PA85 85 g/m² Polyamide white + stripes |

PA100ST 107 g/m² Polyamide pink no stripes |

| 2. PERFORATED FILM |

|

| YES | MICROPOROUS |

| 3. BREATHER / BLEEDER |

|

| PES340 340 g/m² White |

PES150 150 g/m² White |

| Width | Lenght | Thickness |

| 1.50 m | 50 m | +/- 6 mm |

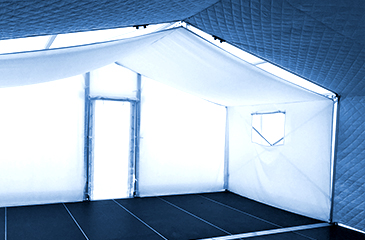

- PROCESS

- Oven

- Autoclave

Documentation

Range of bagging materials for prepregs and hand lay-up composite with vacuum polymerization (271 ko)